The Old Snow Shipyard

75 Mechanic Street Rockland, Maine 04841

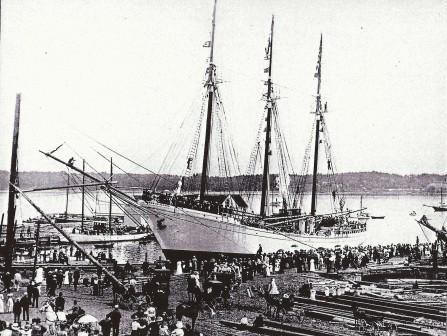

Launch of the Keating 1919

Home for Sharp's Point |

|

|

Sharp's Point South -- The Sail, Power & Steam Museum

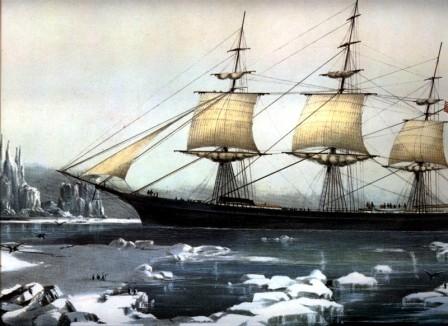

is most fortunate to occupy the hollowed grounds of the old Snow Shipyard. We are proud to be established on acreage that encompassed about half of the original, legendary shipyard site. Rockland Marine, our neighbors on the other half, is an active and productive yard, doing both new construction and ship repairs just as the Snow family did from 1862 until 1937. The yard was, for all those 75 years, truly a family business. The Snows built more vessels than any yard in Maine and in fact most of New England as well. Down the list of their accomplishments are 61 documented vessels: ships, schooners, sloops, barks and brigs as well as several excursion steamboats. They were all built to the highest specifications possible. These were undoubtedly some of the finest vessels that sailed the seas. The Snow family, all seamen and sea captains, knew what a vessel should be and how it should be built. "She is a Snow vessel" was the highest kind of praise from those who follow the sea. It was a well deserved and a frequent tribute to the Snow family shipyard in those days.

The hey-day of the Snow Shipyard was in the 1800s and up to the early 1900s when they built more vessels than than anywhere in New England and had

several hundred employees including shipwrights, master builders and a compliment of talented artisans from riggers to painters. To build a vessel, one must start with wood, raw wood from the virgin forests in many East coastal states from Maine to Georgia. The wood came in by the millions of board feet, by rail, by schooner and even by horse cart. Before the construction began, these great logs were immersed in the salt pond for pickling. The salt water of the harbor would leach the sap from the raw logs replacing it with the

salt of preservation, seasoning the stock for the sawyer to shape into parts and pieces for the building process. They would then be slabbed, axed and dubbed entirely by hand into the shape of the frames, knees and other parts of a vessel. Frame after interminable frame would be stood up until the entire shape of the vessel, sometimes over three hundred feet long, would be evident. With the stem and transom

already in place, it became time for the planking crew to turn to. The frames would have to be dubbed flat where the plank would lay in against and each frame would be aligned with the rest from bow to stern true and fair. With many a grunt and grown the heavy planking was hung. Those with lots of shape to them would be heated in the steam box and while still hot and juicy, they would be wound into place by men balancing on a swaying piece of plank precariously

blocked up temporarily under the new vessel. There was no OSHA here, all was accomplished with the true grit of strong men, and damn the spleeny.

With the outside of the vessel receiving heavy white oak planking, the ceiling crew will often start to seal up the inside where she will be storing her cargo. This inner planking when caulked lends great strength to the entire structure. It is frequently even a heaver dimension than that on the outside and was commonly the finest Georgia hard pine. The decking crew shapes the deck beams with specific crown and starts the decking planking while the joiners carve out the deck erections, hatches, windless, wheel box andvery often a voluptuous officers quarters back aft. With the bulwark, rails and a million other pieces of deck hardware, the riggers will soon grapple with masts, booms and gaffs, shrouds and stays, bowsprit and jib boom. When the caulkers have made in the oakum in planking, ceiling and deck, and the seams are tarred and puttied, the painting crew spreads fresh Baltimore copper on the bottom and a creamy coat of white on the topsides. Then crowds of spectators come from the farms for miles around by horse, by buggy or shoe-sole transportation and the vessel is dressed with flags on every mast. A launching was always a major event even in a city like Rockland where literally hundreds of huge wooden ships were constructed and this kind of spectacular was by no means a rarity.

Launching of the Hugh De Payne, April 1893Come and visit the Sail, Power & Steam Museum and get acquainted with these magnificent vessels that sailed from and helped to build the city of Rockland.

Get on the mailing list...receive information...volunteer for your museum!

Call Captain Jim at 207-701-7627 or 701-5050